Abstract

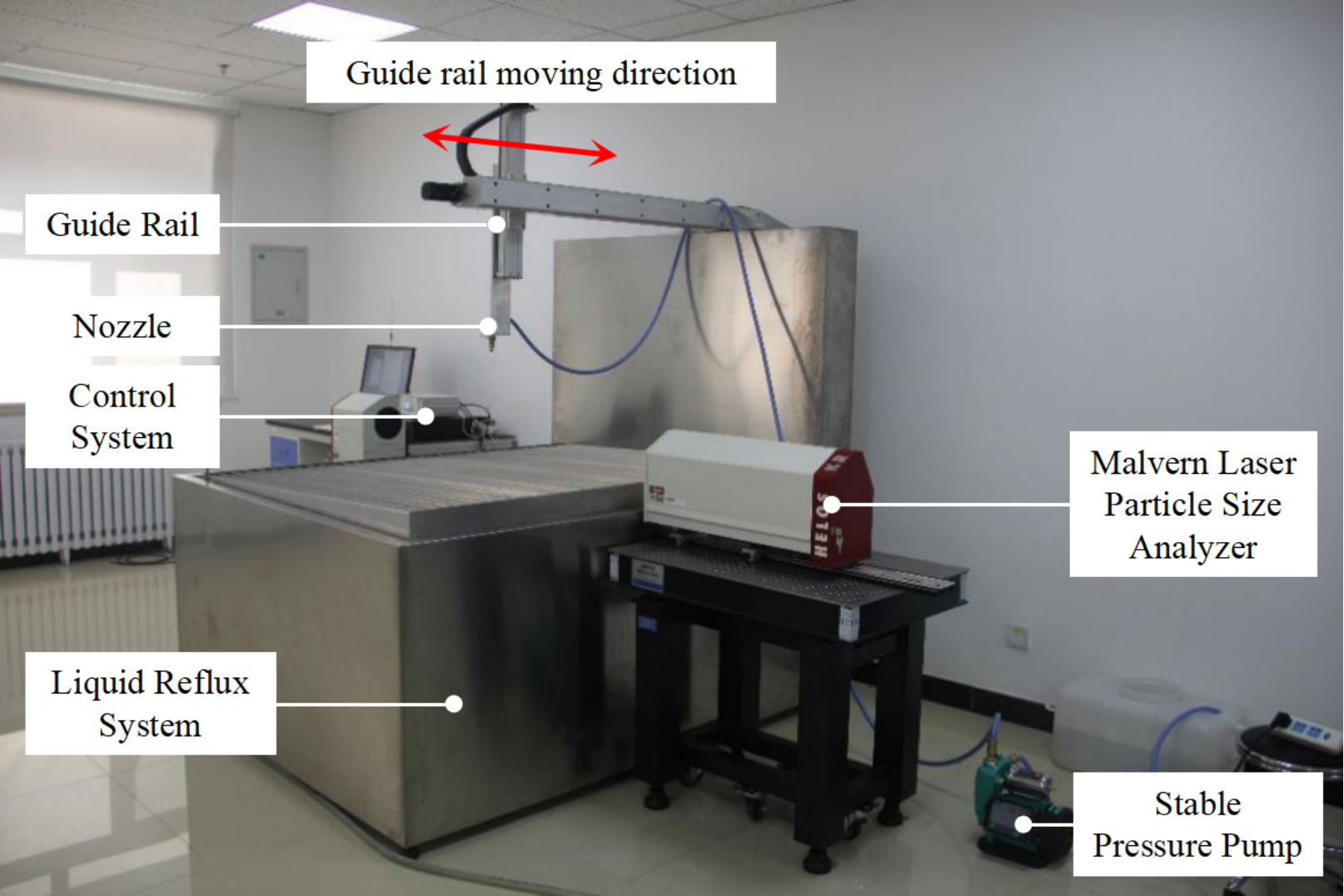

Precision plant protection, a crucial facet of precision agriculture, assumes a paramount role throughout diverse stages of agricultural pesticide utilization. It not only furnishes indispensable reference parameters for agricultural production but also minimizes the employment of pesticides and their environmental footprint. This investigation employs a laser particle size analyzer to gauge the particle size information of the atomization field under assorted conditions, commencing with ground plant protection. The findings reveal that particle size escalates with the ascent of spray pressure and spray angle while diminishing with their augmentation. It proposes that pressure adjustments can optimize atomization outcomes when the deposited atomized droplet size is suboptimal. This study provides a data foundation for pesticide atomization in ground plant protection procedures and presents corrective actions for inadequate sedimentation effects, thereby mitigating the environmental harm associated with agricultural endeavors.

Keywords

Atomization parameters

Atomization parameters

particle size

precision plant protection

weight

Funding

This research was supported by Science and Technology Innovation Talent Program (Grant No. 2022zz096).

Cite This Article

APA Style

Ma, H., Tang, J., Lv, H., Chu, W., & Sun, S. (2024). Investigation on the Mechanism of Nebulized Droplet Particle Size Impact in Precision Plant Protection. IECE Transactions on Intelligent Systematics, 1(2), 102-111. https://doi.org/10.62762/TIS.2024.307219

Publisher's Note

IECE stays neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Institute of Emerging and Computer Engineers (IECE) or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

Submit Manuscript

Edit a Special Issue

Submit Manuscript

Edit a Special Issue